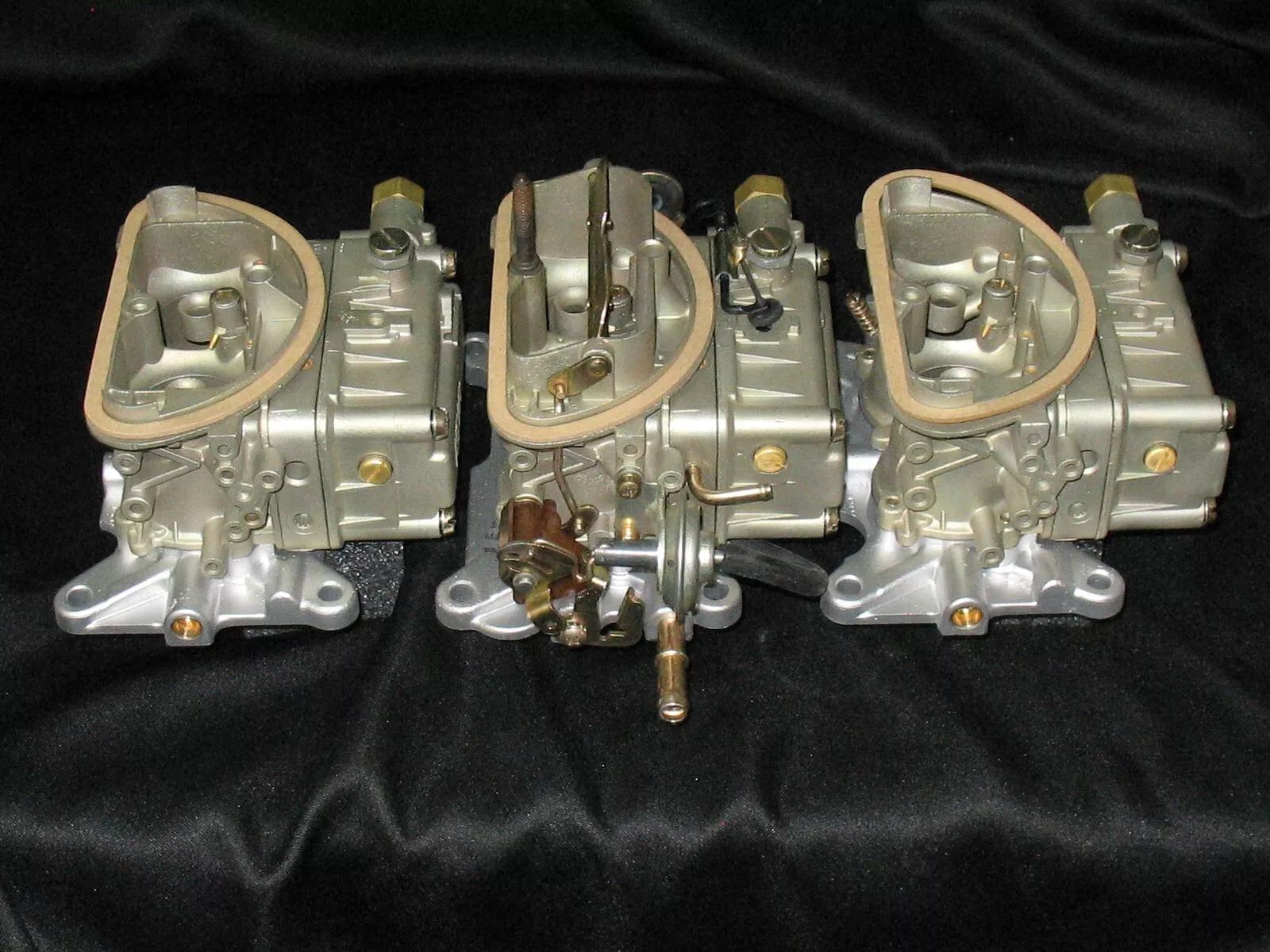

Are you looking for expert carburetor restoration services for your vintage or muscle car? Custom Rebuilt Carburetors, a family-owned business since 1979, specializes in restoring show-quality carburetors for classic cars. Whether you drive a Ford Mustang, Chevy Corvette, or Dodge Charger, we’ll ensure your carburetor runs like new. Contact us today to breathe new life into your engine with precision and expertise!

If you restoring a classic muscle car and need a reliable carburetor expert to bring your engine back to life? At Custom Rebuilt Carburetors, we specialize in the precision restoration and repair of carburetors for all your vintage, muscle, and classic cars. Whether you own a Ford Mustang, Chevy Corvette, or a rare Pontiac GTO, our team brings over 40 years of experience rebuilding even the hardest-to-find carburetors to show-quality standards. From high-performance Holley and Edelbrock models to complex Quadrajet rebuilds, we’ve got you covered. All our carbs undergo wet flow testing and come with a factory warranty, so your car will perform flawlessly at the next car show or on the road.

If you’re serious about restoring your classic car to its former glory or simply need expert help with a rare or difficult carburetor, send your carburetor to Custom Rebuilt Carburetors today! Let us handle the fine-tuning while you focus on getting that perfect show finish!

Understanding the Anatomy of a Carburetor

To truly appreciate the level of craftsmanship that goes into each carburetor restoration, it’s important to understand the key parts:

Key Parts of a Carburetor: Understanding Their Role in Your Engine’s Performance

To fully appreciate the precision and expertise required in rebuilding carburetors, it’s important to understand the key components that make up this critical engine part. A well-functioning carburetor is essential to ensuring optimal air-fuel mixture, which in turn, powers your classic or muscle car smoothly and efficiently.

Throttle Body

The throttle body plays a vital role in controlling the amount of air and fuel mixture that enters the engine’s combustion chamber. When you press the accelerator, the throttle plate inside the throttle body opens, allowing more air to flow into the engine. The engine’s fuel injectors then adjust the amount of fuel based on the amount of airflow, resulting in more power. If the throttle body becomes worn or clogged, it can lead to a poor throttle response, rough idling, or even stalling during acceleration. Proper calibration of the throttle body is key to smooth performance.

Float Chamber

The float chamber, or fuel bowl, ensures that the carburetor has a constant supply of fuel. Inside the chamber, a float rises and falls with the fuel level, controlling the needle valve, which opens or closes to allow fuel in from the fuel line. This system prevents flooding or starving the engine of fuel, keeping the fuel level at an optimal point. If the float becomes damaged or misadjusted, it can cause fuel overflow (flooding) or insufficient fuel delivery, leading to performance issues such as stalling or power loss. Rebuilding the float chamber is essential for achieving a consistent fuel supply.

Venturi

The venturi is a narrow section of the carburetor where the air speed increases, creating a pressure drop. This low pressure pulls fuel into the airflow from the jets, creating the ideal air-fuel mixture required for combustion. The shape and size of the venturi are crucial for efficiency and engine power. A blocked or worn venturi can result in a poor fuel mix, which affects overall engine performance and fuel efficiency. Proper venturi function is essential for keeping your engine running smoothly, especially at higher RPMs.

Jets

Jets are tiny precision parts that control the amount of fuel delivered to the engine based on the airflow. There are different types of jets in a carburetor, including the main jets, idle jets, and secondary jets, each playing a role in various throttle positions. When jets become clogged with dirt or debris, they can restrict fuel flow, leading to lean conditions (too little fuel), which cause misfires, hesitation, or engine overheating. On the flip side, worn jets may allow too much fuel (rich condition), causing flooding, rough idle, or black smoke from the exhaust. Ensuring the jets are clean and properly sized is key to maintaining the engine’s performance.

Choke

The choke helps during cold starts by restricting airflow to enrich the fuel mixture. When your engine is cold, it needs more fuel to start and run properly. The choke temporarily blocks some of the incoming air, allowing the engine to get a richer (fuel-heavy) mix, which helps it start easier. A malfunctioning choke can cause hard starts, excessive fuel consumption, or even stalling once the engine warms up. Restoring or adjusting the choke is critical to ensuring smooth cold starts and consistent engine operation as the car warms up.

Understanding how these components work together helps explain why maintaining or rebuilding a carburetor is so important for your car’s performance. When one part is worn or misaligned, it throws off the entire air-fuel balance, affecting everything from horsepower to fuel efficiency. That’s why Custom Rebuilt Carburetors specializes in not only restoring these parts but fine-tuning them for peak performance.

Each of these components plays a vital role in ensuring your engine runs smoothly. Over time, these parts can wear out, leading to a range of performance issues.

Classic Car Carburetors and Their Common Issues

Each make and model has its own unique carburetor challenges. Here’s a detailed look at common problems faced by classic car owners:

Ford

- Ford Mustang (1964–1980s):

Mustangs often suffer from hard starting and rough idle, particularly due to clogged jets or a sticking throttle body. Owners of the early models frequently encounter fuel leaks from worn gaskets, leading to poor fuel economy. - Ford Galaxie (1959–1974):

Issues with the Galaxie carburetor often involve sluggish acceleration and engine stalling, caused by a faulty float chamber or an improper air-fuel mixture. Hard starting in cold weather is also common, due to choke problems. - Ford Torino (1968–1976):

Many Torino owners report carburetor flooding, especially after the car has been sitting for a while. This is usually due to a worn needle valve or improper float level. - Ford Thunderbird (1955–1982):

The Thunderbird carburetor tends to develop vacuum leaks over time, resulting in rough idle and stalling. These issues are often caused by cracked or dried-out vacuum lines connected to the carburetor. - Ford F-Series Trucks (up to the early 1980s):

F-Series trucks frequently encounter poor throttle response and loss of power under load. This is commonly linked to blocked fuel jets or throttle shaft wear.

Chevrolet

- Chevrolet Camaro (1967–1980s):

Camaro carburetors are prone to stalling and poor acceleration due to a lean fuel mixture, often the result of dirty jets or a failing float. Another common issue is bogging down during acceleration, especially when the secondaries fail to open correctly. - Chevrolet Corvette (1953–1981):

Corvettes often face throttle body wear, leading to rough idle or hesitating acceleration. Carburetor flooding and hard hot starts are also typical, particularly in older models, due to needle valve or float issues. - Chevrolet Impala (1958–1979):

Impalas are known for developing a “flat spot” on acceleration, where the car stutters before accelerating smoothly. This is usually caused by a worn-out accelerator pump or improperly adjusted jets. - Chevrolet Chevelle (1964–1972):

The most common issue with Chevelles is a high idle, which is often due to air leaks or worn throttle shafts. Owners also report engine stumbling on acceleration, caused by improper jetting or vacuum leaks. - Chevrolet Nova (1962–1979):

Novas frequently experience carburetor backfiring, which can be traced back to lean fuel mixtures or misaligned throttle plates. This can lead to poor fuel efficiency and inconsistent engine performance.

Dodge

- Dodge Charger (1966–1978):

A common complaint with Chargers is hesitation during acceleration, often due to clogged jets or a malfunctioning accelerator pump. Fuel leaks around the throttle shafts are another common issue. - Dodge Challenger (1970–1974):

Challengers often develop problems with sluggish performance and flooding. This usually stems from improperly adjusted floats or worn needle and seat assemblies. - Dodge Dart (1960–1976):

Dart carburetors tend to suffer from poor idle quality and stalling. These issues are usually the result of a misadjusted choke or vacuum leaks around the carburetor base. - Dodge Coronet (1949–1976):

Coronets commonly exhibit rough idling and hard starts, especially in cold weather. This is often due to a faulty choke or worn throttle shafts.

Plymouth

- Plymouth Barracuda (1964–1974):

Barracudas often face poor acceleration and fuel economy problems, usually due to clogged fuel jets or a misadjusted throttle linkage. Flooding during startup is also common. - Plymouth Road Runner (1968–1974):

Owners of the Road Runner frequently report hard starting and engine stumbling, which can be linked to a malfunctioning accelerator pump or improper jetting. - Plymouth Duster (1970–1976):

Dusters tend to develop vacuum leaks over time, leading to stalling or rough idle. These leaks are often caused by worn throttle shafts or gaskets. - Plymouth GTX (1967–1971):

GTX carburetors commonly experience backfiring and rough running conditions, typically due to lean fuel mixtures or clogged jets.

Pontiac

- Pontiac GTO (1964–1974):

GTO owners often face bogging during acceleration, which is usually due to an underperforming secondary throttle or dirty fuel jets. Flooding can also occur when floats aren’t properly set. - Pontiac Firebird (1967–1981):

Firebirds are prone to hard starts, especially after sitting for long periods. This is often caused by dried-out gaskets or a faulty float chamber, leading to poor fuel delivery. - Pontiac LeMans (1961–1981):

LeMans models frequently suffer from carburetor hesitation and poor idle quality, often caused by dirty jets or throttle shaft wear. - Pontiac Bonneville (1957–1981):

The Bonneville carburetor tends to develop vacuum leaks over time, resulting in poor performance and stalling, especially under load.

Buick

- Buick Skylark (1953–1981):

Skylarks often experience surging or misfires under load, typically due to lean fuel mixtures or vacuum leaks in the carburetor base. - Buick Riviera (1963–1979):

Rivieras are known for developing issues with rich fuel mixtures, leading to poor fuel economy and black smoke from the exhaust. This is often caused by a stuck float or worn needle valve. - Buick Electra (1959–1984):

The Electra carburetor can develop stalling and hesitation due to clogged fuel jets or misadjusted choke systems, especially during cold starts.

Oldsmobile

- Oldsmobile 442 (1964–1971):

442 carburetors often have issues with throttle response, especially during hard acceleration. This is usually the result of a worn-out accelerator pump or blocked secondary jets. - Oldsmobile Cutlass (1961–1981):

Cutlasses are prone to high idle and fuel leaks, often caused by throttle shaft wear or improper float adjustment.

Volkswagen

- Volkswagen Beetle (1938–1979):

Beetle carburetors often face stalling and hesitation issues, particularly due to clogged fuel jets or misaligned throttle plates. Fuel leaks around the throttle body are also common. - Volkswagen Karmann Ghia (1955–1974):

The Karmann Ghia carburetor frequently develops rough idle and hard starting issues, which are usually linked to vacuum leaks or a worn choke mechanism. - Volkswagen Type 3 (1961–1973):

Type 3 carburetors often exhibit fuel starvation and stalling problems, typically due to dirty jets or worn fuel pump diaphragms.

Porsche

- Porsche 356 (1948–1965):

356 carburetors are prone to flooding and poor idle, often caused by a malfunctioning float or needle valve. Lean running conditions can also lead to backfiring. - Porsche 911 (1964–1973 carbureted models):

Early 911s frequently suffer from poor throttle response and flat spots during acceleration, usually due to improper fuel jetting or a worn throttle shaft.

BMW

- BMW 2002 (1966–1976):

BMW 2002 carburetors often experience poor acceleration and misfires under load, typically caused by blocked jets or an imbalanced float level. - BMW 3.0 CS (1968–1975):

Common issues with the 3.0 CS carburetor include stalling during deceleration and hard starting, often due to misadjusted throttle linkages or air leaks.

How Do You Know When It’s Time for a Carburetor Rebuild?

Knowing when it’s time for a carburetor rebuild involves paying attention to several symptoms that indicate the carburetor isn’t functioning properly. Here are some key signs to look out for:

1. Poor Engine Performance

- Rough Idling: If your engine is idling rough or stalls frequently, it could indicate that the carburetor is dirty or the fuel mixture is off.

- Hesitation or Stumbling: When accelerating, if the engine hesitates or stumbles, it may mean the carburetor isn’t delivering the correct air-fuel mixture.

- Reduced Power: A noticeable drop in power, especially when climbing hills or carrying a load, could be due to a clogged or malfunctioning carburetor.

2. Starting Issues

- Hard Starting: Difficulty starting the engine, whether it’s cold or hot, can be a sign of a faulty carburetor.

- Flooding: If you notice a strong smell of gasoline or see fuel leaking from the carburetor, it might be flooding the engine.

3. Poor Fuel Economy

- If your vehicle is suddenly consuming more fuel than usual, the carburetor might be delivering too rich of a fuel mixture, leading to inefficient combustion and poor fuel economy.

4. Backfiring or Popping Sounds

- Backfiring through the exhaust or intake can indicate a lean fuel mixture, which might be caused by a clogged jet or passage within the carburetor.

5. Black Smoke from the Exhaust

- Black smoke indicates the engine is running rich, meaning there’s too much fuel and not enough air in the mixture. This can happen if the carburetor’s float is sticking or the needle valve is not seating correctly.

6. Visible Build-Up or Dirt

- If you can see varnish, dirt, or deposits on the outside of the carburetor, there’s a good chance the inside is dirty as well and might need a rebuild.

7. Age and Maintenance History

- If the carburetor hasn’t been serviced or rebuilt in a long time, even in the absence of obvious symptoms, it might be due for a rebuild as part of regular maintenance.

If you’re experiencing one or more of these symptoms, it’s likely time to consider a carburetor rebuild. Rebuilding the carburetor involves disassembling, cleaning, and replacing worn-out parts, which can restore proper fuel flow and improve engine performance. If you’re not comfortable with this process, contact usContact Us so that we may professionally rebuild your carburetor.